No Printing Press, No Problem: How to Build a Bottle Jack Press

Considering that its inception, printmaking has revolutionized the globe as we know it. It gave writers, publishers, and artists the edge of generating copies. In flip, it uncovered additional persons to their get the job done a lot quicker. Some of the earliest printing methods have been employed in China all around the 9th century, which associated using hand-carved blocks. In the 15th century, the Gutenberg push designed printing on a mass scale faster than past approaches. In the electronic age, we may well choose the notion of producing a number of copies of something for granted for the reason that we can have it with a fast scan or a click.

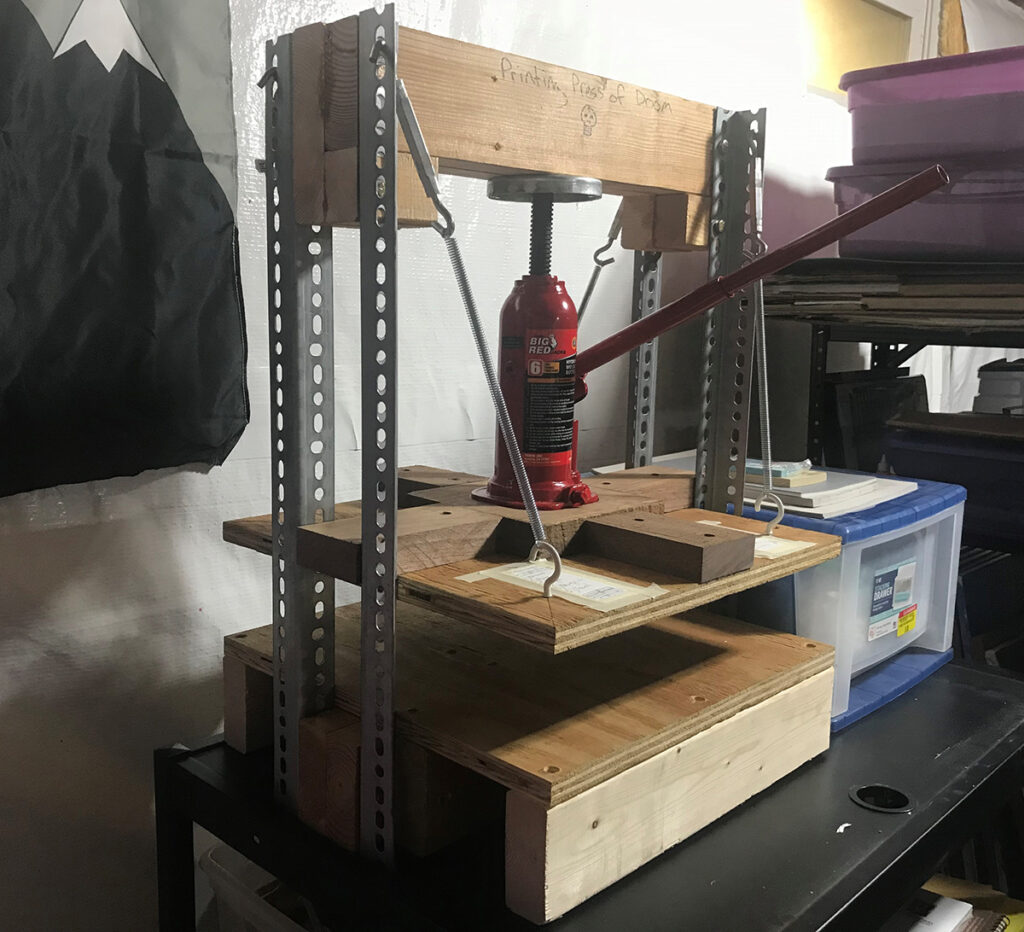

Do not undervalue the printmaking process. Exposing children to this artform is fascinating and opens the door to many artistic choices. Quite a few art instructors opt for hand printing approaches because they do not require a push. If you are fortuitous to have access to a printing press in your studio, think about on your own one particular of the blessed few. If you are exploring for an very affordable push, with a several basic hand and electrical power resources, you can make your have applying an automotive bottle jack.

Dependent on the price ranges of area products, you can make this press for $100–$300. In comparison, most retailers carry etching or platen-design presses for hundreds if not thousands of pounds more. The most pricey buys for this Do-it-yourself are the automotive bottle jack and slotted steel. If you are thrifty, you can buy a bottle jack 2nd-hand as extensive as you guarantee it does not leak and the piston goes up and down efficiently. A 6-ton jack need to suffice for all of your classroom printing demands. If you need everything bigger, it will call for taller slotted steel, which expenditures additional. Nearly anything smaller sized than three-ton might not deliver plenty of pressure for sure print forms.

A further issue to take into consideration is if your university district can put the funds for this build into your artwork funds. If you have to pay back out of pocket, inquire about a reimbursement method. Implementing for a grant is yet another selection to attempt.

Let’s glimpse at the supplies you will require for this develop:

Here’s a checklist of tools you will need:

- Circular, miter, or radial arm noticed (a handsaw will work far too)

- Drill and influence driver with bits

- Tape measure

- Wooden clamps

- Wood glue

When you have collected all of your components and equipment you are ready to construct! The video, How to Build a Bottle Jack Press Demo, is exceptionally practical in visualizing the push and ways. Keep in mind you can modify this in any way to suit your requirements!

In this article are 10 ways to build your bottle jack printing push.

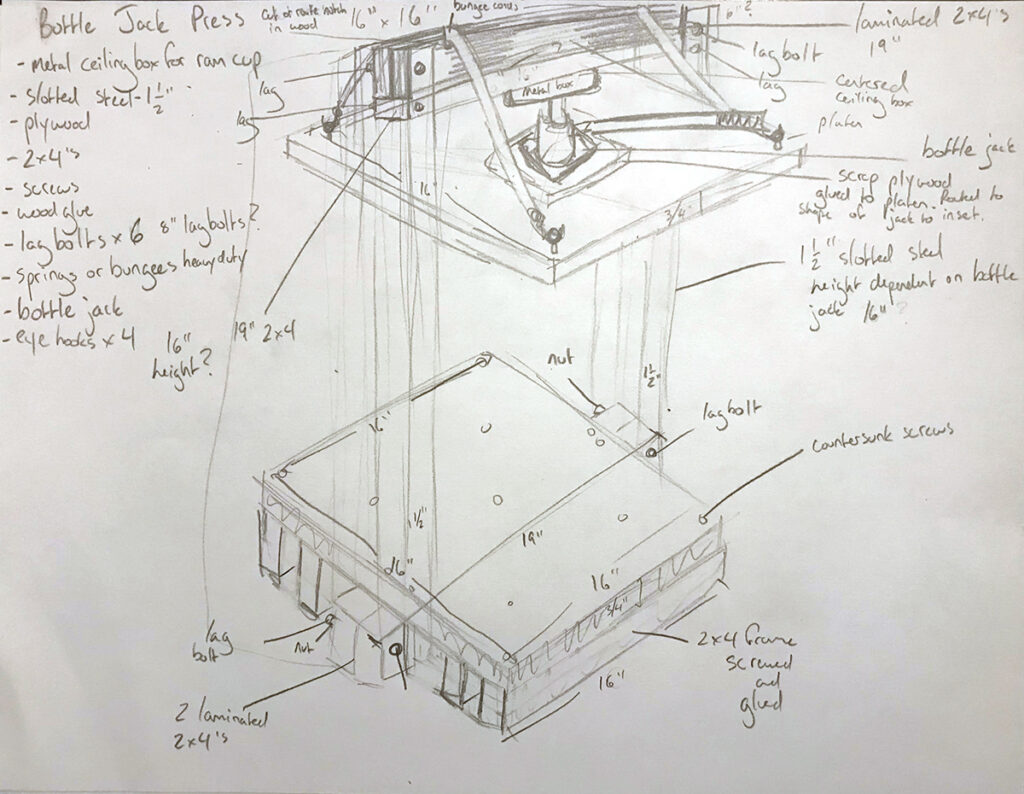

1. Make a sketch and diagram for your build.

Identify all the sizes and proportions of your push like the width, duration, and top. Hold in head to preserve items comparatively smaller sized, even with a 6-ton push. It is highly recommended not to exceed a 20″ width or duration on the foundation.

2. Reduce 2 2 x 4s for the header and then glue and clamp them alongside one another.

At the time dry, set the header piece aside for afterwards. Make confident it sticks out prolonged enough to connect to the slotted metal for a later stage.

3. Minimize 2 2 x 4s for the middle of the foundation and then glue and clamp them alongside one another.

After it dries, this will be the heart of your press base. Ensure it sticks out long more than enough to attach to the slotted metal for a later step.

4. Cut and screw the 2 x 4s to body out the push foundation.

Use the laminated 2 x 4 in the middle of your foundation. Use other 2 x 4s to make a framework for the top of the base.

5. Slice and screw the plywood for the top rated of the base.

Screw the plywood ideal on leading of the 2 x 4 foundation. It is recommended that you countersink your screw heads so they don’t display up on a remaining print.

6. Established up the slotted steel on every single side of the laminated base and insert the laminated header for the major. Then, drill holes and insert the hex bolts.

This aspect can be challenging so use a wood clamp or two to keep the steel in spot although you drill and push your hex bolts. If you do not have an influence driver for the bolts, you can use ratchets and a wrench to safe them in place. Make absolutely sure it is cosy!

7. Connect the metallic electrical box to the header.

Locate the lifeless-heart of your header and screw in the metallic circle or electrical box. This serves as a ram cup for your push so it does not dig into the wooden around time.

8. Reduce a piece of plywood for the platen pressboard.

Make guaranteed the platen push board is the identical size as your plywood foundation.

9. Screw 4 eye hooks onto the platen pressboard. Then connect bungee cords or turnbuckles and springs to the header and eye hooks.

10. Discover the useless-middle of the platen board and location the bottle jack in the center.

It is recommended to make some kind of foundation for the bottle jack so it does not slide about through use.

Let us search at the operation of the push.

- Area your jack on the heart of your platen board.

- Established up your print. It may glance a little unique relying on what type of print you are making.

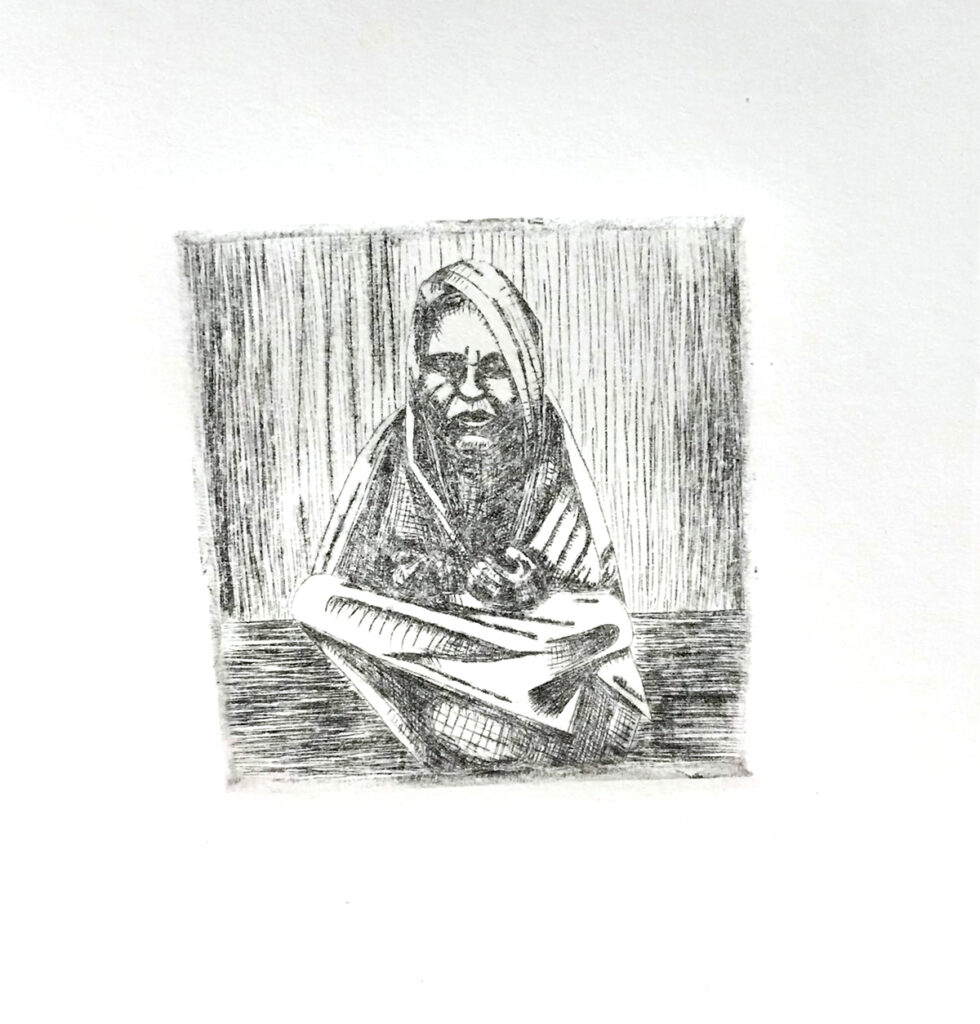

For linocut prints, put a piece of tagboard on the foundation, the inked block, then the paper.

For etching or intaglio prints, position a piece of tagboard on the base, the inked block, printing paper, butcher paper, then a folded towel. - Run the jack as normal. (Check with your owner’s handbook for your specific design.) Most jacks are the very same. Tighten the valve, insert the handle into the piston cup, and pump the piston to increase the jack. In this scenario, raising the jack closes the gap between the platen board and the foundation.

- Pump the jack until eventually the platen or prime board completely meets your print, and you simply cannot pump any more. Be cautious not to overpump your jack, or a catastrophic failure can take place, these as your header board cracking. Don’t forget, these jacks elevate cars and trucks, so it has additional than adequate tension to make your prints!

- Immediately after you simply cannot pump the push any more, launch the valve on your push, which ought to cause the platen board to rise. Slide out your print and admire it!

This selfmade press does consider some follow to use and fine-tune. Use it as a trainer-guided station or for demonstrations in an elementary location. In middle or significant faculty, consider demonstrating your pupils how to use the push and centre it all around a printmaking project of your choice. This press can also handle some bookmaking or embossing assignments. Seize some equipment and get begun developing this bottle jack push. The faster you construct it, the sooner you and your learners can use it!

If you are looking for printmaking lessons and assets, search no more!

How can you see by yourself employing this Do it yourself press in your classroom?

Do you have any modifications or adjustments you would make to this develop? If so, what are they?